Views: 0 Author: Site Editor Publish Time: 2025-06-03 Origin: Site

In today’s advanced industries, many manufacturing and processing operations take place under extreme conditions, including very high temperatures, corrosive chemical atmospheres, and vacuum environments. These harsh conditions pose significant challenges for materials used in critical components, requiring a combination of thermal stability, chemical inertness, and mechanical durability.

Graphite, known for its excellent thermal conductivity and machinability, is widely used in such applications. However, graphite’s natural vulnerability to oxidation and chemical attack limits its direct use in many extreme environments. To overcome these limitations, silicon carbide (SiC) coatings have been developed to protect graphite parts, enhancing their performance and lifespan.

Silicon carbide (SiC) is a ceramic compound made of silicon and carbon atoms arranged in a crystal lattice, renowned for its exceptional hardness, chemical stability, and high melting point. When applied as a coating on graphite components, SiC acts as a protective barrier that significantly enhances the graphite’s ability to withstand extreme thermal and chemical environments. This coating protects the graphite substrate from oxidation, corrosion, and mechanical wear, while preserving the underlying material’s advantageous properties such as thermal conductivity and machinability.

There are two main industrial techniques used to apply SiC coatings onto graphite substrates:

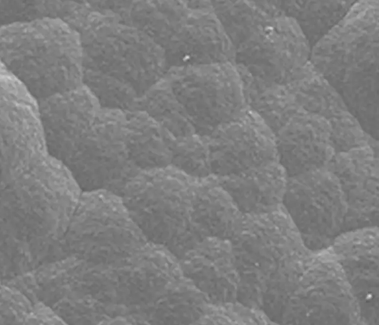

Chemical Vapor Deposition (CVD): This is the most common and effective method for producing dense, uniform, and strongly adherent SiC layers. During CVD, the graphite component is exposed to silicon-containing gases at high temperatures (typically between 1000°C and 1400°C). These gases chemically react on the graphite surface, depositing a thin but robust layer of silicon carbide. The CVD process ensures excellent coating uniformity even on complex geometries and penetrates microscopic pores in the graphite to form a tightly bonded layer.

Physical Vapor Deposition (PVD): PVD techniques, such as sputtering or evaporation, deposit SiC films by physically transferring silicon and carbon atoms onto the graphite surface in a vacuum chamber. While PVD allows precise control over film thickness and composition, it is less common than CVD for coating large or intricately shaped graphite parts due to limitations in coating thickness and penetration.

Typical Base Graphite Grades Used for Coating

The performance of SiC coated graphite components depends not only on the quality of the coating but also on the properties of the underlying graphite substrate. Common graphite grades selected for coating typically feature:

High Density and Fine Grain Size: To minimize porosity and improve mechanical strength, fine-grain isotropic graphite grades are often chosen. These provide a stable, uniform base for coating and help maintain dimensional accuracy.

High Purity: Impurities in graphite can negatively affect thermal and chemical resistance. High-purity grades reduce contamination risks in sensitive applications such as semiconductor processing.

Good Machinability: The graphite should be easy to machine into complex shapes required by advanced industrial components before coating is applied.

By carefully selecting the graphite substrate and applying a high-quality SiC coating, manufacturers create components that combine the best of both materials: graphite’s thermal and machining advantages with SiC’s superior surface protection.

Silicon carbide (SiC) coatings bring a suite of exceptional functional properties that dramatically enhance the performance and durability of graphite components, especially under extreme industrial conditions. These properties are the foundation for SiC coated graphite’s widespread use across demanding applications.

High Thermal Resistance (Up to >2000°C)

One of the most remarkable attributes of SiC coatings is their ability to withstand ultra-high temperatures, often exceeding 2000°C without significant degradation. This makes SiC an ideal protective layer for graphite parts used in high-temperature environments such as furnaces, plasma reactors, and semiconductor processing chambers. The ceramic nature of SiC ensures it does not soften or melt under these conditions, providing a stable barrier that preserves the structural integrity of the underlying graphite.

Corrosion and Oxidation Resistance

Graphite on its own oxidizes rapidly at elevated temperatures when exposed to oxygen or reactive gases, limiting its lifespan in many applications. SiC coatings create an impermeable shield that resists oxidation and chemical attack from corrosive environments including fluorine, chlorine, and other aggressive plasmas used in semiconductor etching or chemical vapor deposition (CVD). This resistance extends the component’s useful life and maintains process purity by preventing graphite degradation products from contaminating sensitive materials.

Superior Hardness and Wear Protection

SiC’s intrinsic hardness—comparable to that of diamond—makes it highly resistant to mechanical wear and abrasion. This property is essential in industrial environments where coated graphite parts may be subject to friction, particle impact, or mechanical stress. The coating protects critical surfaces such as wafer boats, susceptors, or reactor liners, ensuring consistent performance over extended operational cycles.

Gas-Tight and Chemically Inert Surfaces

SiC coatings form a dense, gas-tight layer that blocks the diffusion of gases and vapors through the porous graphite substrate. This is particularly important in vacuum and plasma processing systems where even minor leaks can compromise process control or contaminate wafers. Furthermore, the chemically inert nature of SiC means it does not react with process gases or byproducts, contributing to a stable, contamination-free manufacturing environment.

Together, these functional properties position SiC coated graphite as a critical material in environments where thermal, chemical, and mechanical challenges must all be simultaneously managed.

The unique combination of silicon carbide’s protective properties with graphite’s thermal conductivity and machinability enables SiC-coated graphite components to excel in a variety of extreme industrial settings. Below are some key industries and processes where these components are indispensable:

Semiconductor Fabrication (Etching, Diffusion, Ion Implantation)

Semiconductor manufacturing relies on precise and contamination-free environments. Processes such as plasma etching, chemical vapor deposition (CVD), diffusion, and ion implantation expose materials to high temperatures and aggressive reactive gases. SiC coated graphite components—like wafer boats, susceptors, and chamber liners—provide the necessary thermal stability and chemical resistance to survive these conditions without degrading or releasing contaminants, ensuring high device yields and process reliability.

Photovoltaic and LED Production

The production of solar cells and LEDs involves processes similar to semiconductor fabrication, including high-temperature crystal growth, diffusion, and annealing steps. SiC coated graphite parts are widely used as susceptor plates, boat carriers, and heating elements due to their ability to maintain dimensional stability, resist chemical attack, and deliver uniform heating—critical factors for producing high-quality photovoltaic wafers and LED substrates.

Metallurgy, Aerospace, and Vacuum Furnaces

In metallurgy and aerospace industries, SiC coated graphite components serve as furnace linings, thermal shields, and structural supports in vacuum and controlled atmosphere furnaces. Their resistance to oxidation and thermal shock, combined with excellent thermal conductivity, makes them ideal for processes like powder metallurgy, metal sintering, and high-temperature annealing. Additionally, the low weight and high strength of SiC coated graphite help improve furnace efficiency and component lifespan under cyclic thermal stresses.

Overall, the durability, chemical inertness, and thermal performance of SiC coated graphite enable it to meet the rigorous demands of harsh industrial environments where alternative materials often fail or require frequent replacement.

Compared to uncoated graphite, SiC coated graphite exhibits:

Extended Lifecycle: Coated parts significantly reduce oxidation and corrosion damage, lowering replacement frequency and maintenance costs.

Enhanced Suitability for Harsh Atmospheres: SiC coatings allow graphite to be used safely in reactive gases, plasmas, and vacuum conditions where uncoated graphite would fail rapidly.

Weight and Machinability Benefits: While metals and ceramics can resist high temperatures, they often lack graphite’s lightweight nature and ease of machining into complex shapes, which is preserved with SiC coated graphite.

Cost-Effectiveness: Although SiC coating adds processing costs, the increased durability and reduced downtime often translate into lower total cost of ownership.

Alternative materials like pure ceramics or metals can be brittle, heavier, or less thermally conductive, making SiC coated graphite a balanced and versatile solution for many extreme environment challenges.

SiC coated graphite components represent a significant technological breakthrough, perfectly meeting the rigorous demands of today’s extreme industrial environments. By merging the natural advantages of graphite with the exceptional protective properties of silicon carbide coatings, these components offer superior thermal stability, chemical resistance, mechanical strength, and ensure high process purity. Their outstanding performance across semiconductor manufacturing, photovoltaics, metallurgy, aerospace, and vacuum furnace applications highlights their essential role in advancing production technologies.

For industries seeking reliable, durable materials that withstand extreme temperatures, corrosive chemicals, and vacuum conditions, SiC coated graphite is the ideal solution—delivering enhanced longevity, improved efficiency, and cost savings. To explore high-quality SiC coated graphite products and tailored solutions, we recommend contacting SIAMC Advanced Materials Co., Ltd. Their expertise and advanced technologies can help you achieve optimal performance for your most demanding applications. Visit their website or reach out directly to learn more about how their SiC coated graphite components can elevate your industrial processes.