On April 23, 2025, during the 3rd Jiufengshan Forum (JFSC) and Compound Semiconductor Industry Expo (CSE), the Third Generation Semiconductor Industry Technology Innovation Strategic Alliance (CASA) officially released two standards for isostatic graphite used in silicon carbide (SiC) single crystal

Read More

Can a single bond protect an entire furnace? High temperature graphite glue keeps vacuum systems sealed and stable, even under extreme heat.With SIAMC products, you will learn how the right adhesive choice extends component life and performance. Learn more about our products.

Read More

Can one bond control both heat and power flow? Conductive graphite glue helps carbon systems stay stable, efficient, and reliable.With SIAMC products, you will learn how the right adhesive improves thermal and electrical performance. Learn more about our products.

Read More

Can a cleaner bond protect your entire process? High purity graphite glue helps reduce contamination in extreme heat systems.With SIAMC products, you will learn how the right adhesive supports purity, stability, and long-term performance. Learn more about our products.

Read More

Is sourcing industrial Graphite Glue harder than it seems?This Graphite Glue sourcing guide explores how material choices shape safety and uptime.In this article, you will learn how SIAMC products improve compatibility and bonding efficiency.Learn more about our products.

Read More

How much are unplanned shutdowns really costing your plant? Professional Graphite Glue cost savings turn routine repairs into long-term value. In this article, we explore maintenance reduction for graphite heat exchangers using SIAMC products. You will see how better bonding cuts risk and spend; learn more about our products.

Read More

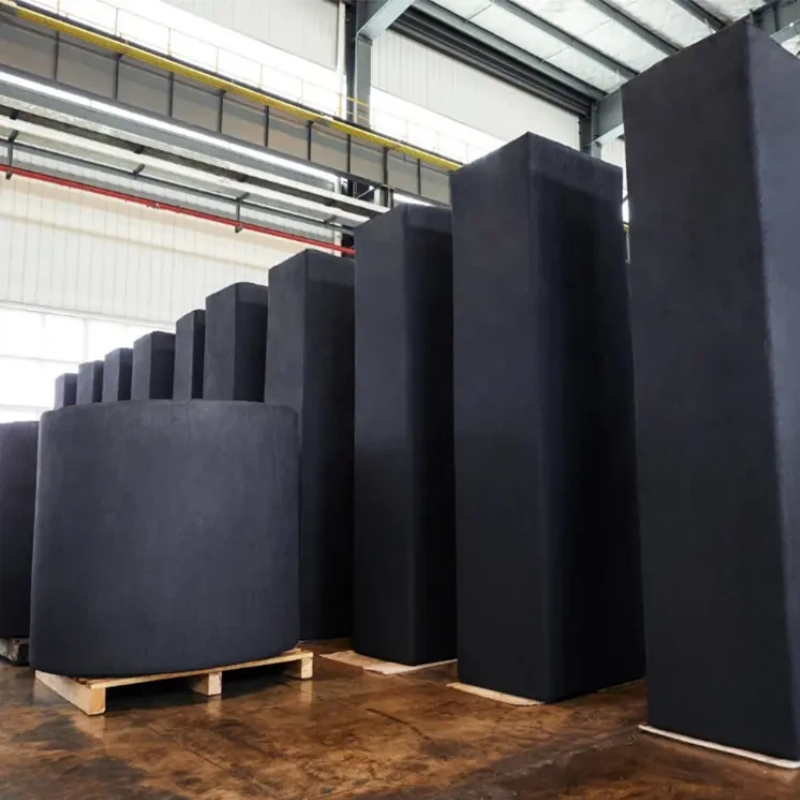

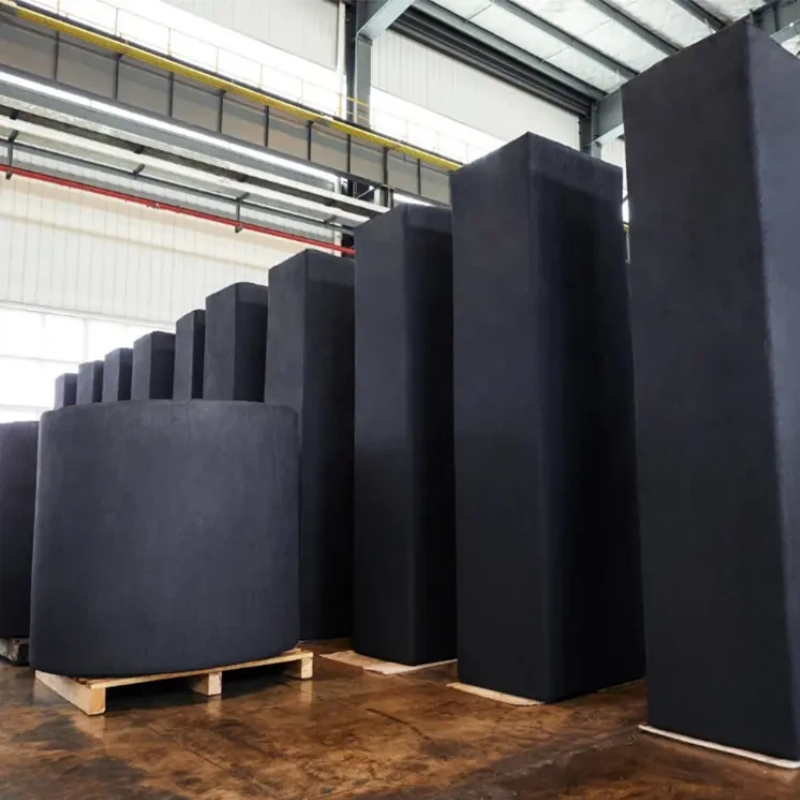

High Purity Isotropic Graphite is a unique material celebrated for its ability to provide consistent performance under extreme conditions.

Read More

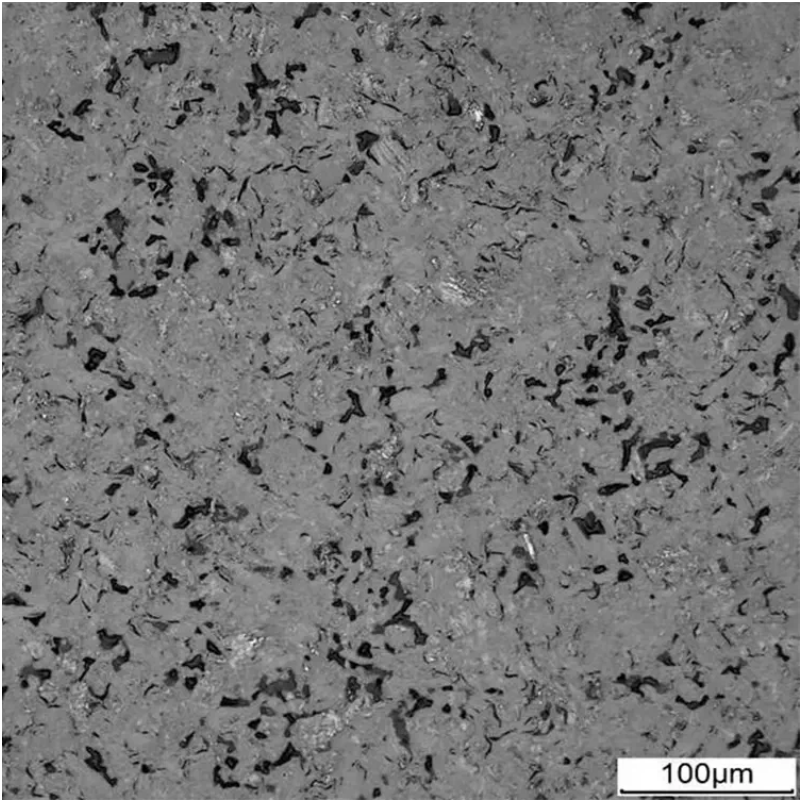

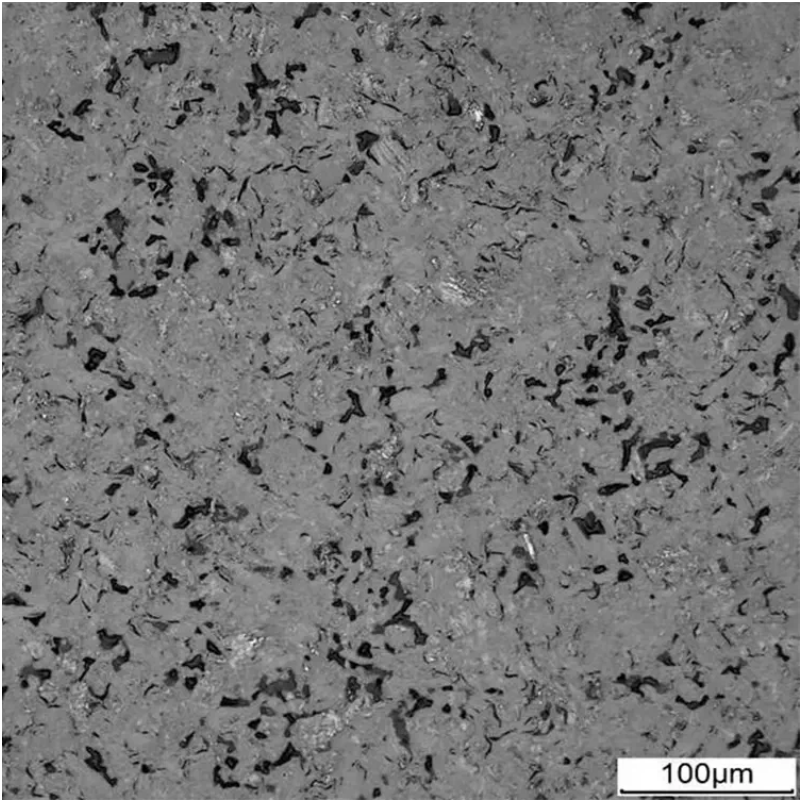

Graphite glue is an advanced adhesive designed specifically for bonding graphite and carbon-based materials.

Read More

High Purity Isotropic Graphite is a cutting-edge material used across various industries due to its exceptional properties, such as high thermal conductivity, mechanical strength, and uniformity in structure.

Read More