Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

The semiconductor industry is one of the most advanced and fast-growing sectors in modern technology. It demands materials that not only perform efficiently but also withstand extreme conditions, including high temperatures, pressure, and chemical exposure. Coated graphite parts play a crucial role in meeting these demands. These parts are designed to enhance the properties of graphite, making it more durable and resistant to the harsh environments commonly encountered in semiconductor manufacturing. This article will delve into the key applications of coated graphite parts in the semiconductor industry, highlighting their essential role in wafer production, etching, and other critical processes.

In semiconductor manufacturing, materials used in production processes must meet extremely high standards of precision, durability, and stability. Graphite has long been favored for its excellent thermal conductivity, electrical properties, and machinability, making it a go-to material for various applications, including wafer boats, susceptors, and liners. However, uncoated graphite can deteriorate under high heat, chemical exposure, and mechanical stress, leading to shorter lifespans and reduced performance in semiconductor equipment.

Coated graphite parts, enhanced with coatings such as pyrolytic carbon, silicon carbide (SiC), and tantalum carbide (TaC), provide an ideal solution to these challenges. Coatings add protection against oxidation, thermal shock, and corrosion, ensuring that graphite components maintain their integrity and performance in demanding semiconductor processes. In this article, we will explore how these coatings enhance the properties of graphite parts, particularly in critical applications such as chemical vapor deposition (CVD) chambers, plasma etching, and epitaxy.

Wafer fabrication is a delicate process that involves several critical steps, including CVD, ion implantation, and doping. For these processes, materials like graphite are commonly used in components such as wafer boats and susceptors. These parts are subjected to extreme temperatures, which can reach over 1000°C, and must maintain dimensional stability to ensure the quality of the semiconductor wafers.

Thermal Stability: Graphite’s ability to withstand high temperatures makes it a valuable material for wafer fabrication. However, uncoated graphite can suffer from oxidation and thermal shock at elevated temperatures, leading to failure. Coatings such as SiC and pyrolytic carbon enhance graphite’s resistance to these issues, ensuring the material’s longevity and reliability.

Precision: In semiconductor processes, precision is crucial. The material used must remain stable to ensure that the intricate patterns required for microelectronics are accurately etched onto the wafer surface. Coated graphite provides the dimensional stability needed for these precise processes.

While uncoated graphite is a cost-effective material, coated graphite parts offer several key advantages in semiconductor manufacturing:

Oxidation Resistance: Uncoated graphite can degrade rapidly at high temperatures due to oxidation, reducing its effectiveness in high-heat processes like CVD. Coated graphite parts, on the other hand, are protected by coatings that resist oxidation, extending their lifespan and maintaining their performance.

Durability: Coatings such as SiC and pyrolytic carbon provide enhanced protection against wear, corrosion, and thermal shock, which uncoated graphite cannot withstand. This added durability ensures that coated graphite components can endure the rigorous conditions of semiconductor production for longer periods, reducing the need for replacements.

Cost-Effectiveness: Although coated graphite parts may initially cost more than uncoated graphite, their enhanced performance and durability lead to long-term cost savings by reducing maintenance, downtime, and the need for frequent replacements.

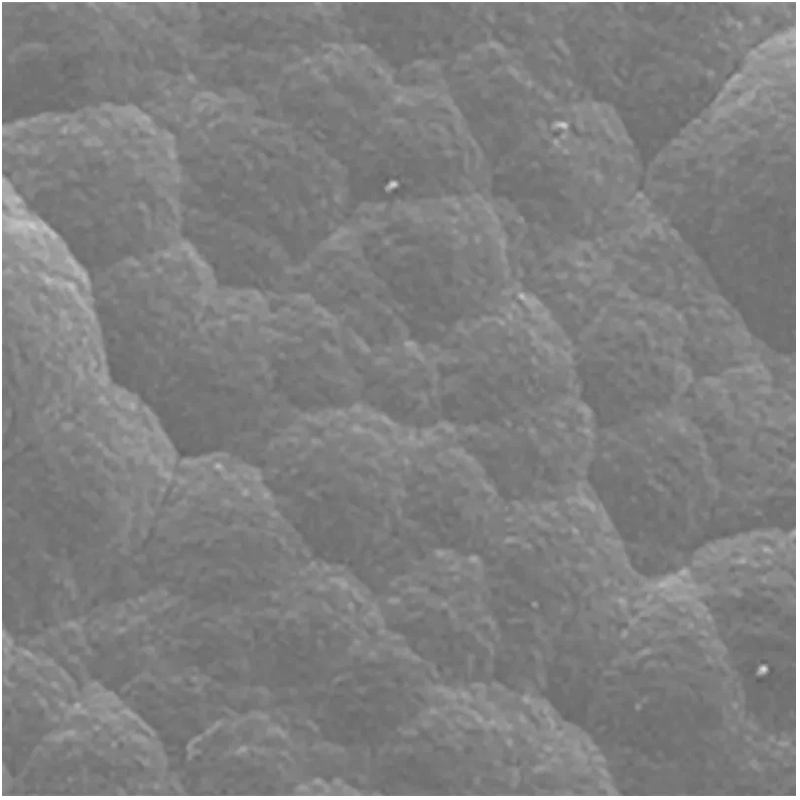

Pyrolytic carbon is one of the most widely used coatings in the semiconductor industry, particularly for components like wafer boats and susceptors. The coating is applied through a process called chemical vapor deposition (CVD), which results in a thin, dense carbon layer on the surface of graphite.

Thermal Resistance: The pyrolytic carbon coating improves graphite’s ability to withstand high temperatures, making it ideal for CVD chambers where materials are exposed to extreme heat.

Stability: The coating also enhances the material's stability, preventing it from degrading when subjected to thermal shock, which is common in semiconductor processes.

Applications: Pyrolytic carbon-coated graphite is commonly used in wafer boats, susceptors, and thermal shields in CVD and plasma etching processes, where high temperatures and precise temperature control are critical.

Silicon carbide (SiC) is another popular coating used in semiconductor manufacturing due to its excellent heat resistance and chemical stability. The SiC coating is applied through high-temperature CVD, which creates a hard, impervious layer that protects graphite from oxidation and wear.

High-Temperature Resistance: SiC-coated graphite can withstand extreme temperatures without degrading, making it ideal for semiconductor processes like plasma etching and chemical vapor deposition.

Chemical Resistance: The SiC layer also provides resistance to chemical exposure, ensuring that graphite components remain intact even when exposed to corrosive gases used in semiconductor fabrication.

Durability: The coating’s hardness improves the wear resistance of graphite, making SiC-coated graphite parts ideal for long-term use in high-stress environments.

Tantalum carbide (TaC) is a highly effective coating for semiconductor equipment exposed to aggressive chemicals. The TaC coating is applied through methods like CVD and plasma spraying, creating a highly durable layer on the graphite surface.

Corrosion Resistance: TaC-coated graphite is highly resistant to chemical corrosion, particularly in environments exposed to metal vapors and reactive gases.

High-Temperature Performance: TaC also provides excellent high-temperature performance, making it suitable for semiconductor processes that involve elevated temperatures and harsh chemical exposure.

Applications: TaC-coated graphite is commonly used in nuclear reactors, high-performance furnaces, and semiconductor manufacturing where both chemical and thermal resistance are required.

One of the key advantages of coated graphite parts is their enhanced thermal and chemical resistance. Coatings such as SiC, pyrolytic carbon, and TaC provide protection against oxidation, wear, and corrosion, which allows graphite to perform effectively in harsh semiconductor processes that involve high heat and chemical exposure.

Protection from Heat: The coatings ensure that graphite can maintain its structural integrity even when exposed to extreme temperatures, which is crucial in CVD, plasma etching, and other high-temperature semiconductor processes.

Chemical Stability: The coatings also protect graphite from the aggressive chemicals used in semiconductor production, ensuring that the materials maintain their performance and durability.

The dimensional stability of coated graphite parts is essential in semiconductor manufacturing, where precision is paramount. The coatings ensure that the graphite components maintain their size and shape, even under extreme conditions, helping to preserve the quality of the semiconductor wafers.

Maintaining Wafer Quality: By providing enhanced dimensional stability, coated graphite parts help to ensure that the wafer quality is consistent throughout the production process, leading to higher yields and better-quality products.

The durability of coated graphite parts significantly reduces the need for maintenance and replacements in semiconductor equipment. Since the coatings protect graphite from oxidation, wear, and chemical exposure, the parts last longer, which reduces the overall cost of ownership.

Lower Operational Costs: By increasing the longevity of coated graphite parts, companies can reduce the frequency of replacements and minimize downtime, ultimately leading to lower operational costs.

Reduced Maintenance: The enhanced durability of coated graphite parts translates to less frequent maintenance, further reducing costs and improving productivity in semiconductor operations.

Coated graphite parts play a crucial role in semiconductor manufacturing, providing the durability, precision, and stability needed to perform in extreme conditions. Coatings like SiC, pyrolytic carbon, and TaC enhance the thermal, chemical, and mechanical properties of graphite, making it an ideal material for use in critical processes like wafer production, plasma etching, and CVD. These coated parts ensure consistent performance, improve efficiency, and reduce maintenance costs, helping semiconductor manufacturers meet the growing demands of the industry.

By selecting high-performance materials like coated graphite parts, companies can ensure the reliability and longevity of their equipment, improving both product quality and operational efficiency. The surface treatment of graphite is key to enhancing its performance and extending its lifespan, making it a crucial consideration for businesses in semiconductor manufacturing. To learn more about how coated graphite parts can benefit your semiconductor manufacturing processes, explore SIAMC’s catalog for high-quality graphite solutions tailored to your specific needs. Contact us today for more information.

Q1: Why are coated graphite parts essential in semiconductor manufacturing?

A1: Coated graphite parts provide enhanced thermal resistance, chemical stability, and dimensional precision, which are crucial for high-performance semiconductor manufacturing.

Q2: How does pyrolytic carbon coating improve graphite for semiconductor use?

A2: Pyrolytic carbon coating enhances graphite’s heat resistance and oxidation resistance, making it ideal for high-temperature processes like CVD and plasma etching.

Q3: What is the role of SiC-coated graphite in semiconductor equipment?

A3: SiC-coated graphite offers excellent chemical resistance and wear protection, making it ideal for high-temperature environments such as chemical vapor deposition and plasma etching.

Q4: Can coated graphite parts reduce maintenance costs in semiconductor manufacturing?

A4: Yes, coated graphite parts offer long-term durability, reducing the need for frequent replacements and minimizing maintenance costs in semiconductor equipment.