Views: 0 Author: Site Editor Publish Time: 2025-06-09 Origin: Site

Graphite is an essential industrial material known for its unique properties, including excellent electrical conductivity, thermal resistance, and machinability. However, one critical yet often overlooked factor in graphite's performance is grain size. Whether the graphite is fine-grained or coarse-grained can significantly affect its behavior in various applications, from semiconductor manufacturing to metal casting.

Understanding the microstructure of graphite is vital for selecting the right grade for your specific process. Grain size affects strength, thermal expansion, surface finish, and cost—all of which directly impact manufacturing outcomes. This blog post explores the key differences between fine and coarse grained graphite and helps you determine which material is best suited to your industrial needs.

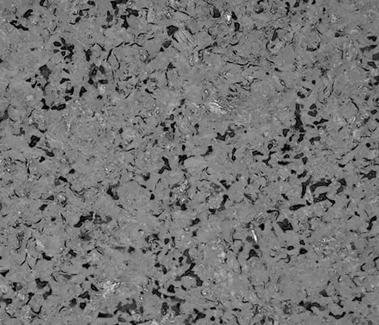

Grain size in graphite refers to the average diameter of the particles or crystallites that compose the bulk material. These grains are formed during the graphite manufacturing process when raw carbon materials are compacted, baked, and graphitized at extremely high temperatures.

Fine grained graphite is typically defined as having particle sizes less than 20 microns (μm), and in many cases as low as 5 μm or even sub-micron. These extremely small particles pack tightly together, resulting in a highly dense and uniform material structure.

Coarse grained graphite, on the other hand, contains much larger particles, often greater than 75 microns, and sometimes extending up to 200–300 μm. The structure of coarse grained graphite is more porous, with visible granularity.

Grain size is more than just a physical measurement; it is directly correlated with the graphite’s mechanical performance, surface smoothness, thermal behavior, and machinability. The smaller the grains, the more consistent the material properties throughout the component.

Graphite Type | Grain Size (µm) | Typical Use Case |

Ultra-Fine Grained | <5 µm | High-precision EDM, semiconductor molds |

Fine Grained | 5–20 µm | EDM electrodes, vacuum furnace parts |

Medium Grained | 20–75 µm | Casting molds, foundry equipment |

Coarse Grained | >75 µm | Ingot molds, general refractory uses |

The production of graphite with a specific grain size involves precise control over raw material selection, mixing, forming, and graphitization processes. Some of the most common methods include:

Isostatic Pressing: Often used to produce fine grained graphite. In this method, pressure is applied uniformly from all directions, resulting in highly isotropic material with consistent density and grain size throughout the volume.

Molded Graphite: Used for both fine and coarse grained types. It involves uniaxial pressing of graphite powder in a mold, followed by baking and graphitization.

Vibration Molding: Commonly used for medium to coarse grained graphite. This process allows the formation of large blocks and is more cost-effective for bulk production.

Extrusion: Frequently used for cylindrical shapes, like rods and tubes. While it supports both fine and coarse grain, it's less isotropic than isostatic pressing.

The choice of manufacturing process not only affects grain size but also determines the final product’s mechanical strength, uniformity, and cost.

Understanding how fine and coarse grained graphite differ in physical and mechanical properties is essential for choosing the right material for a specific industrial task. These differences stem directly from the microstructure and density of the graphite, which influence its performance under heat, pressure, and machining.

Fine grained graphite typically has higher bulk density and compressive strength than its coarse-grained counterpart. Because the small particles pack more tightly, there are fewer internal voids or porosities. This tighter structure enhances overall mechanical integrity and resistance to fracture.

Fine Grained Graphite: High density (~1.80–1.90 g/cm³), compressive strength up to 100 MPa or more.

Coarse Grained Graphite: Lower density (~1.60–1.75 g/cm³), compressive strength typically below 60 MPa.

This makes fine grained graphite ideal for applications where structural reliability under mechanical stress is crucial, such as in EDM electrodes or semiconductor molds.

Graphite is renowned for its excellent thermal conductivity. However, grain size affects how efficiently heat is conducted and how much the material expands when exposed to high temperatures.

Fine Grained Graphite: Offers more uniform thermal conductivity, typically in the range of 80–120 W/m·K. It also has a lower coefficient of thermal expansion (CTE), providing better dimensional stability during rapid heating or cooling cycles.

Coarse Grained Graphite: While still thermally conductive, the irregular particle interfaces can cause localized thermal stress or uneven heat distribution in some cases.

Fine grained graphite also exhibits superior thermal shock resistance, meaning it can withstand rapid changes in temperature without cracking—a key advantage in thermal cycling environments.

One of the most practical differences lies in how each material behaves during machining:

Fine Grained Graphite: Can be machined to tighter tolerances and finer surface finishes. This is especially valuable in precision components where surface quality impacts performance, such as dies for glass molding or EDM electrodes used in fine-feature production.

Coarse Grained Graphite: More prone to edge chipping or rougher surface finishes due to the larger particle size, which limits its usability in high-precision applications.

Fine grained graphite is especially favored in industries where accuracy, consistency, and longevity are critical. These include electric discharge machining (EDM), semiconductor tooling, and specialized molds for glass and metal forming.

In electrical discharge machining (EDM), graphite electrodes are used to erode metal in complex shapes through controlled sparks. The performance of the electrode is directly influenced by the graphite’s grain size.

Fine Grained Graphite delivers:

High wear resistance, extending electrode lifespan.

Smooth cavity finishes on the workpiece.

Accurate replication of fine details and sharp corners.

Lower breakage risk due to better strength and dimensional stability.

These advantages translate into faster machining cycles, fewer tool changes, and better part quality—factors that significantly affect production efficiency and cost.

For mold making, especially in semiconductor and LED manufacturing, dimensional stability under heat is paramount. Fine grained graphite provides:

Minimal thermal deformation, reducing defects in molded components.

High wear resistance, which minimizes tool replacement frequency.

Low ash content, which is critical for contamination-sensitive environments.

These traits ensure consistent part replication, fewer rejects, and longer mold service life.

Because of its finer grain structure and excellent machinability, fine grained graphite is ideal for creating intricate and detailed geometries. It supports:

Thin walls

Sharp angles

Small radii

Tight tolerances (±0.01 mm or better)

This is especially important in industries such as aerospace, electronics, and medical device manufacturing, where design precision and repeatability are critical.

Fine grained and coarse grained graphite each serve important roles in modern industry. Choosing the right type depends on your application's specific demands. Fine grained graphite excels in strength, machinability, and thermal stability—ideal for precision tools like EDM electrodes, semiconductor molds, and high-performance fixtures. In contrast, coarse grained graphite is a more economical choice for large-scale crucibles, structural supports, and general thermal applications.

If your project requires exceptional accuracy, minimal thermal expansion, and long-term durability, fine grained graphite is the clear solution. For tailored material recommendations and high-purity graphite products, we invite you to connect with SIAMC Advanced Materials Co., Ltd. Our team is ready to support your most demanding applications with customized solutions. Visit our website or contact us today to learn more.