Views: 0 Author: Site Editor Publish Time: 2026-01-19 Origin: Site

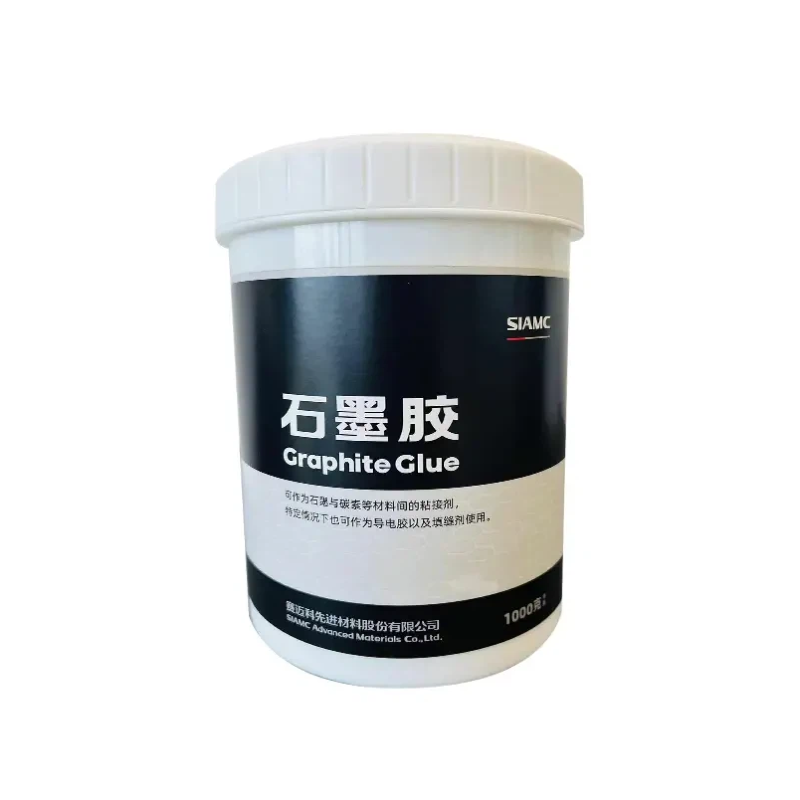

Can a single bond protect an entire furnace? High temperature graphite glue keeps vacuum systems sealed and stable, even under extreme heat.With SIAMC products, you will learn how the right adhesive choice extends component life and performance. Learn more about our products.

Inside a vacuum furnace, components such as heating elements, liners, and graphite fixtures must stay fixed in place. Standard adhesives soften or burn away under heat. Industrial graphite glue forms a carbon-based bond that stays stable even as temperatures climb beyond the limits of most materials. This strength keeps internal parts aligned, which helps maintain even heat flow and prevents physical distortion during long production runs. In facilities that use high-purity graphite parts, operators often rely on graphite glue systems designed to match the thermal behavior of the base material, reducing stress at the joint.

Vacuum furnace graphite bonding is not only about strength. It is also about sealing. Small gaps in seams or joints allow oxygen to enter. Oxygen reacts with graphite at high heat and causes rapid degradation. A high heat resistant graphite adhesive fills cracks and joints, forming a dense layer that limits gas flow and supports a clean, controlled atmosphere. This sealing role becomes especially important in semiconductor and photovoltaic thermal processes, where process purity directly affects yield.

Graphite fixtures often carry heavy workpieces. Thermal expansion and vibration place stress on bonded areas. Graphite glue strength depends on its low expansion rate and high mechanical stability. This combination helps joints resist cracking during repeated heating and cooling cycles. Over time, this stability can reduce the need for frequent re-alignment or part replacement.

Industrial graphite glue is designed for operating ranges that reach well beyond standard ceramics and epoxies. Many formulations remain stable in inert or vacuum environments up to 2500°C or higher. This thermal stability allows bonded components to survive long processing cycles without losing adhesion or turning brittle. In high-end furnace systems, this property protects both structural and functional graphite parts from early failure.

Materials expand when heated. If an adhesive expands faster than the parts it bonds, stress builds at the joint. Graphite adhesive for high temperature applications has a low coefficient of thermal expansion. This means it grows and shrinks at a rate close to graphite itself. This match reduces the risk of cracks during rapid temperature changes, such as those found in batch sintering or brazing processes.

Graphite glue often retains some thermal and electrical conductivity. This helps spread heat more evenly across bonded surfaces and reduces the chance of localized hot spots. Even heat flow supports consistent furnace performance and can protect sensitive components such as thermocouple mounts and heating element connections.

Adhesive Type | Max Temperature Range | Thermal Expansion | Heat Conductivity | Suitability for Vacuum Furnace |

Standard Epoxy | Up to 250°C | High | Low | Poor |

Ceramic Cement | Up to 1500°C | Medium | Low | Moderate |

Industrial Graphite Glue | Up to 2500°C+ | Low | Medium | Excellent |

High temperature graphite glue is non-metallic and carbon based. It does not release vapors that contaminate the furnace atmosphere. This low outgassing behavior is critical in precision industries such as semiconductor wafer processing and high-purity metal sintering, where even trace contamination can affect final product quality.

Many furnace processes involve reactive gases or molten metals. Graphite bonding solutions resist acids, alkalis, and carburizing atmospheres. This chemical stability helps joints last longer in aggressive thermal environments, including induction furnaces and continuous heat treatment systems.

Process purity matters in high-value manufacturing. Using industrial graphite glue reduces the risk of metal particles or organic residues entering the hot zone. This makes it suitable for clean thermal applications where high-purity graphite components are paired with advanced carbon or ceramic assemblies.

If a glue softens under heat, bonded parts can shift or fall. This may damage heating elements, crack liners, or collapse internal fixtures. Repairs in these areas are often expensive and time consuming, especially when high-density graphite or carbon composite parts are involved.

A poor seal allows oxygen to enter the furnace. Oxygen reacts with graphite at high temperatures and causes rapid burning. This shortens the life of insulation, heating elements, and graphite felt, leading to frequent replacements and higher operating costs.

Frequent failures lead to more shutdowns. Each shutdown reduces production time and raises labor costs. Over months, these losses often exceed the initial savings from choosing a lower-grade adhesive instead of a purpose-built graphite glue solution.

Ceramic cements handle moderate heat but often become brittle. They may crack under vibration or thermal cycling. Graphite glue offers more flexibility and better shock resistance, making it better suited for long-term furnace operation.

Bolts and clamps create stress points. They expand differently than graphite and can loosen over time. Bonded joints distribute stress evenly across a surface, reducing the chance of localized failure.

Graphite adhesive for high temperature applications often costs more than basic options. However, longer service life and fewer repairs can reduce total lifecycle cost, especially in systems that rely on expensive graphite fixtures and precision components.

Method | Heat Resistance | Shock Resistance | Installation Speed | Long-Term Stability |

Mechanical Fastener | High | Low | Medium | Medium |

Ceramic Cement | Medium | Low | Slow | Low |

Graphite Glue | Very High | High | Fast | Very High |

Bonding surfaces must be clean and dry. Dust, oil, and oxidation reduce contact strength. Light roughening can increase surface area and improve grip. This step is especially important when working with high-purity graphite or carbon fiber composites.

Many graphite glues come in powder form and are mixed with a liquid binder to form a paste. The paste should be smooth and uniform. Application can use brushes, syringes, or spatulas, depending on joint size and geometry. This flexibility supports both large structural repairs and fine-detail bonding.

Some adhesives cure at room temperature. Others gain strength during initial heating. Controlled ramping during first use helps form a stable bond layer that matches the thermal behavior of the surrounding graphite parts.

Operators should wear gloves and eye protection during preparation. Fine powders can irritate skin and lungs. Good ventilation reduces inhalation risk during mixing and application.

Graphite adhesive supports clean furnace operation. Its non-metallic structure limits vapor release and residue formation, helping protect sensitive thermal processes.

Store powder in dry containers. Moisture can affect performance. Cured waste is often inert and easier to dispose of than chemical resins or metal-filled adhesives.

Strong bonding reduces movement and wear. This protects liners, molds, and fixtures from early failure. Facilities using premium graphite components often see longer maintenance intervals when paired with compatible graphite glue systems.

Graphite glue allows quick patching of cracks and joints. Repairs often complete in hours instead of days. This reduces downtime and supports continuous production schedules.

Stable joints support even heating and consistent results. This improves product quality and reduces variation across batches.

Not all glues handle the same heat levels. Choose formulations rated for your maximum furnace temperature and atmosphere type, whether vacuum, inert gas, or controlled air.

Some adhesives bond better to graphite than to ceramics or metals. Check compatibility with all surfaces in the joint, especially when working with carbon composites or coated graphite parts.

Consistent quality matters. Technical data sheets and test samples help confirm performance before large-scale use. Industrial users often prefer suppliers that specialize in both graphite components and matching accessory materials, ensuring better material compatibility and long-term support.

Laboratory tests often report tensile strength between 6 and 20 MPa. Thermal cycle testing may exceed 1000 cycles without visible cracking. These figures show how industrial graphite glue supports long service life in demanding furnace environments.

A steel heat treatment plant repaired furnace liners using graphite adhesive. After six months, unplanned shutdowns dropped by nearly one third. The improved seal reduced oxidation damage and extended liner life.

An aluminum foundry used graphite glue to refurbish worn graphite molds. Scrap rates fell by over 15 percent. Mold life doubled under repeated thermal cycles, lowering overall production cost.

Graphite glue may cost more per unit than ceramic cement. However, fewer repairs and less downtime often lower total expense across the full lifecycle of a furnace system.

Better seals reduce heat loss. Lower heat loss means less power use over time, which can translate into measurable energy savings in continuous operations.

Stable joints allow scheduled maintenance instead of emergency repairs. This helps control labor and spare part costs, especially in facilities running multiple high-temperature furnaces.

Cost Factor | Low-Grade Adhesive | Graphite Glue |

Initial Price | Low | Medium |

Repair Frequency | High | Low |

Downtime Cost | High | Low |

Total Lifecycle Cost | High | Medium |

High-temperature strength drives reliable vacuum furnace performance. The right graphite glue protects structure, seals joints, and preserves process purity. By matching adhesive choice to heat, chemistry, and materials, operators reduce downtime and extend equipment life. With SIAMC, users gain graphite glue solutions that align with graphite components, delivering durable, efficient, and long-term furnace value.

A: High temperature graphite glue bonds graphite parts, seals joints, and supports stable, clean operation under extreme heat.

A: It reduces oxidation, resists thermal shock, and extends the life of graphite components in high heat environments.

A: It offers better shock resistance, flexibility, and long-term stability during repeated heating cycles.

A: It enables fast repairs, strong seals, and reliable vacuum furnace graphite bonding.